pusher centrifuge|pusher centrifuge pdf : factories The important parameters are screen area, acceleration level in the final drainage zone and cake thickness. Cake filtration affects residence time and volumetric throughput. Residence on the screen is controlled by the screen's length and diameter, cake . See more Resultado da 18 de mai. de 2021 · Nick Rodriguez, commonly known as Nicky Rod, is a professional grappler – no-gi jiu-jitsu specialist – and former amateur wrestler who worked extensively .

{plog:ftitle_list}

WEBLyric Finder - Search the world's best lyric sites and find lyrics for any song.

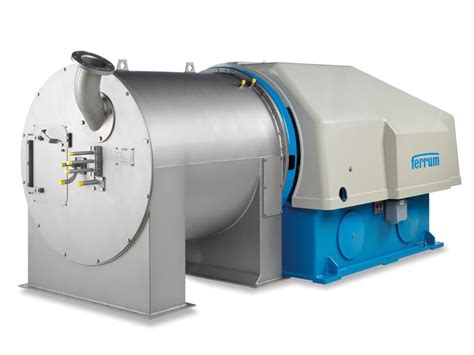

A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of a constant speed rotor and is fixed to one of several baskets. This . See more

Pusher centrifuges are mainly used in chemical, pharmaceutical, food (mainly to produce sodium chloride as common salt) and mineral industries. During the twentieth century, the pusher . See moreAdvantages• Pushers offer higher processing capacities than batch filtering centrifuges such as vertical basket and inverting filter. See moreThe designs for pusher centrifuge are as follows:Pushers come with eithermechanical and/or hydraulic drive units. Speed can vary.Single-stageSingle-stage units . See more

The important parameters are screen area, acceleration level in the final drainage zone and cake thickness. Cake filtration affects residence time and volumetric throughput. Residence on the screen is controlled by the screen's length and diameter, cake . See more

The heuristics of pusher centrifuge design consider equipment size, operation sequence and recycle structure.Design processOverall approach: See moreProductionThe majority of liquid contained within the mixture is drawn out at an early stage, in the feed zone of the slot screen. It is discharged into the filtrate housing. After formation of solid cakes, the main by-product produced is . See moreDesign advances have enhanced performance and broaden the application range. These include additional stages, push hesitation, horizontal split process housing, integrated hydraulics, seals, pre-drained funnels and an integrated thickening function. See more

The Krauss-Maffei pusher centrifuge SZ is a reliable and efficient centrifuge for solid liquid separation. It has a gentle product acceleration, a pre-filtration technol.Operating principle of the D-ACT ® pusher centrifuge. The centrifuge is continuously fed with the suspension to be separated (solid-liquid mixture) via the inlet pipe. The distributor accelerates and distributes the suspension over the .

B&P Littleford is a manufacturer of pusher centrifuges for separating coarse solids from free-draining crystalline slurries. The pusher centrifuge has .

The SHS pusher centrifuge is a high-performance machine for separation work in crystalline and polymer applications. It offers individual design variants, low residual moisture, high solid yield . Learn how pusher centrifuge works for solid-liquid separation in the chemical and mineral industries. Find out the scale-up variables, design features, and benefits of this . Learn how pusher centrifuges have improved product quality, energy efficiency and operations over the last decade. Discover the features and benefits of Andritz's ecoOne . Learn about pusher centrifuge, a type of filtration technique that can de-water and wash materials such as relatively incompressible feed solids, free-draining crystalline, .

The SIEBTECHNIK pusher centrifuge fulfils its separation task reliably and efficiently in numerous applications for the chemical, pharmaceutical and food industries.

pusher centrifuges for sale

pusher centrifuges successfully combine the features of high availability with minimum maintenance and reduced specific space requirement. Especially suited for fast filtering .

Pusher centrifuges are often operated with highly corrosive and abrasive products. In such applications, regular inspections and maintenance are essential to ensure the efficiency and safe operation of the centrifuges. ANDRITZ . A pusher centrifuge is a device that uses centrifugal force to separate solids and liquids in a continuous process. The working principle of a pusher centrif.A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of .

We have been in the field of manufacture of pusher centrifuge for over Two decade. we pride ourselves on our unwavering dedication to engineering excellence and customer-centric solutions. With decades of experience in centrifuge manufacturing, our team of experts meticulously crafts each centrifuge system to exacting standards, ensuring .

The pusher centrifuge belongs to the group of conti-nuously working filtration centrifuges. The solids are retained as a cake on the wedge wire basket and trans-ported by an oscillating step-by-step movement of the inner basket axially in the direction of the solids dischar-ge. With the pusher centrifuge, the transport speed ofthe pusher motor is to generate the axial, alternating pushing force that moves the solid cake step by step through the centrifuge. HYDRAULIC PUSHER DRIVE Pusher centrifuges with a hydraulic pusher drive offer very high throughput rates as a result of their high pusher force and high G-force. Machine sizes with aThe D-ACT® pusher centrifuge System Escher Wyss extends the application range of the pusher centrifuge selection towards products with good dewatering characteristics. Its mechanical basis is built upon the highly successful pusher centrifuge range type P-60 to P-100. The unique patented design of the D-ACT ® pusher centrifuge leads to product Features of Pusher Centrifuge. A pusher centrifuge comes with hydraulic drive arrangements for different capacity requirements. The safety features available in a pusher centrifuge include gas tight arrangement, interlock mechanism for the front lid, anti-vibration interlock, safety guard, and pressure relief valve for high capacity, large units.

A pusher centrifuge is a continuously operating filtration centrifuge used for processing bulk products in the chemical or mineral industries. This article looks at pusher centrifuge technology over the last decade and how it has redefined product quality, energy efficiency and operations.That is where pusher centrifuges come into play to assist in the solid-liquid separation process. For many years, pushers have been used to remove liquid from crystals to minimise breakage and impurities in mineral production. If your company is looking to replace a pusher centrifuge, we have a selection of used options.The Krauss-Maffei pusher centrifuge is a continuous filtration centrifuge for solid liquid separation. It is designed to perform reliable and efficient even under rough process conditions. Day by day. 3000 sold units and more than 150 years of expierience speak for themselves. The continuous development and the adaption to changing requirements .

The B&P pusher centrifuge has a reputation as a rugged machine that operates reliably year after year with minimal repairs. However, B&P maintains a crew of experienced service specialists who will be dispatched to help you get your machine back in service should the need arise. B&P can also execute major rebuilding projects on old machines . The two-stage pusher centrifuge is a kind of continuous operation centrifuges, and is widely used in light industry, chemical industry, metallurgy, coal and other industries.Pusher centrifuge is a type of continuous filtration centrifuge that offers dewatering and washing materials continuously. it has been widely used for solids-liquid separation, such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances.A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of a constant speed rotor and is fixed to one of several baskets. This assembly is applied with centrifugal force that is generated mechanically .

A pusher centrifuge is a specialized machine used for the separation and classification of solids and liquids in a wide range of industries. It is widely recognized for its efficiency, reliability, and ability to handle large volumes of .Allcentrifuges is the top centrifuge machine manufacturer in China, with centrifuges from as early as 2009 still being used globally. Our machines play a crucial role in separating sugar crystals in the sugar processing industry, as well as in the chemical and pharmaceutical industries for solid-liquid separation. https://www.siebtechnik-tema.com/shs-pusher-centrifuge/The SIEBTECHNIK TEMA SHS pusher centrifuge has established and proved itself as a modern high-performa.salt pusher centrifuge Our salt centrifuge allows for precise liquid-solid separation process and further washing and purification of the crystals while reducing the humidity of the salt. A continuous separation process engineered to combine .

Pusher centrifuge is a continuous filtering device used for solid-liquid separation which finds extensive use in chemical, pharmaceutical, food (common salt) and mineral industries. Pushers have been in use for more than half a century for dewatering relatively large, free-draining crystals and other solids.The Pusher Centrifuge is a relatively low speed industrial centrifuge for continuous dewatering processes. The centrifuge drum supports a wedge-wire screen that is driven by a single electric motor controlled by a variable speed inverter, VSD. The rotation of the drum at speed creates the centrifugal force that is the key to the separation. The pusher centrifuge consists of a rotating perforated drum lined with a slot screen and a push plate reciprocating with a frequency of about 1 Hz, with a variable advance of between 30 and 60 mm. At first sight, the mechanical design of a tumbler appears complicated, but the construction is simple in comparison with other types of continuous .

Another example of a continuous centrifuge is the pusher centrifuge. These are used to separate coarse solids from slurry mixtures. In order to do this, the slurry is deposited on the feed screen where liquors drain through and solids collect (1 and 2 in the diagram below). Next, the pusher plate moves the solid film forward, exposing more .Continuously running pusher centrifuges demand continuous feeding conditions A continuous feed is the sine qua non of continuously running pusher centrifuges. The correct thickening of the inflowing suspension ensures optimal functioning of the pusher centrifuge. Ferrum’s range of different thickening and dosing de-Krauss-Maffei SZ pusher centrifuge Operation Special discharge design Vane-type feed distributor Discharge conditions A special feature of Krauss-Maffei pusher In addition to the pre-acceleration the resid- The two flows of filtrate and solids are dis- centrifuges is the vane-type feed distributor. ual moisture can be influenced by a variable charged separately from the .

HR Pusher Type Centrifuge is a type of filtering centrifuge characterized by continuous feeding and intermittent discharging. Composed of hydraulic system, pushing mechanism, base, enclosure, transmission mechanism, basket, etc., this product is able to realize continuous feeding, separation, washing, discharging and other processes at full .

Looking for reliability in performance? Proven, yet innovative separation technology? With a one-of-a-kind maintenance concept? An experienced supplier who t.

pusher centrifuge supplier

Resultado da TOGETHER parte 5, 3D, Abuelos, Blowjob, Incesto, Mamadas, Masturbacion, Tios

pusher centrifuge|pusher centrifuge pdf